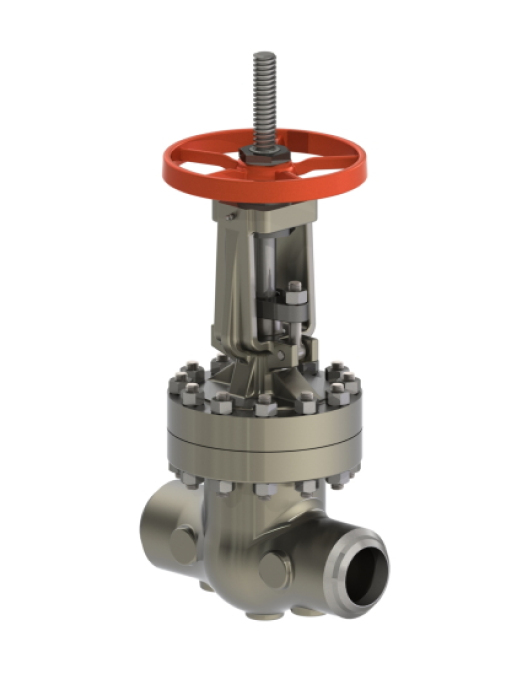

A rising stem gate valve has a stem that extends upward as the valve opens, offering clear visibility of the valve's position. This feature makes it easy to monitor the valve’s status and facilitates straightforward operation. Ideal for high-pressure and temperature applications, it ensures reliable performance and durability.

| Design Standard | API 600/150 10434/AP160/15014313/ΑΡΙ 803 |

| Inspection & Testing Standard | API 598/150 5208 |

| Face to Face | As Per ANSI B 16.10 |

| End Connection | Flanged End To ANSI B16.5/85 10 Table PS/PN/DIN/15 Standard, Screwed End To ANSI 1.20.1 (B5J/NFT), Socket Weid End To ANSI 8 16.11. Buttweld End To ΑΝ Β 10.25 |

| Size Range | 1/2" Το 24" (DN15 Το DN600) (If higher sizes required, please do contact us) |

| Pressure Rating | 150, #300, #600, #800, #900, #1500 |

| Operation | Hand Wheel/Gear Operated (As applicable/As requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

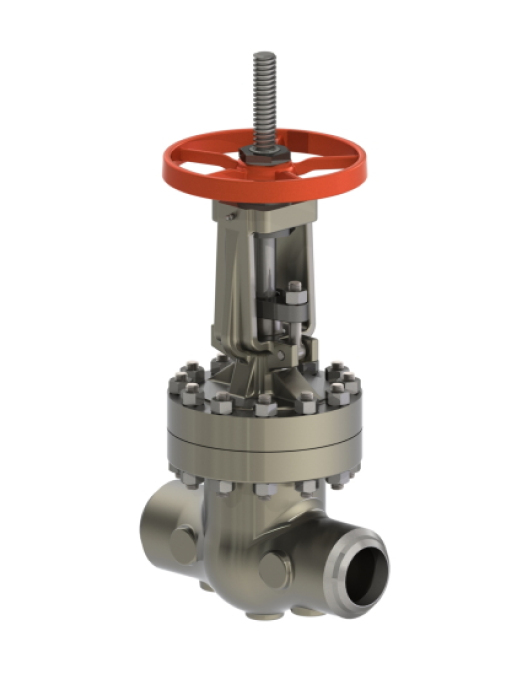

The OS & Y (Outside Stem and Yoke) gate valve has an external stem and yoke, allowing clear visibility of the valve's open or closed position. This design simplifies operation and maintenance while protecting the stem from the flow media. Ideal for high-pressure and temperature applications, it offers durability and easy access for operators.

| Design Standard | API 600/150 10434/AP160/15014313/ΑΡΙ 803 |

| Inspection & Testing Standard | API 598/150 5208 |

| Face to Face | As Per ANSI B 16.10 |

| End Connection | Flanged End To ANSI B16.5/85 10 Table PS/PN/DIN/15 Standard, Screwed End To ANSI 1.20.1 (B5J/NFT), Socket Weid End To ANSI 8 16.11. Buttweld End To ΑΝ Β 10.25 |

| Size Range | 1/2" Το 24" (DN15 Το DN600) (If higher sizes required, please do contact us) |

| Pressure Rating | #150, #300, #600, #800, #900, #1500 |

| Operation | Hand Wheel/Gear Operated (As applicable/As requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

Gate valves are robust on/off control devices designed to provide a full, unobstructed flow path when fully open, making them ideal for applications where minimal pressure drop is essential. They operate by lifting a gate or disc out of the flow path, ensuring a tight seal when closed to prevent leakage. Gate valves are commonly used in high-pressure and high-temperature applications where reliable isolation is critical, offering durability and straightforward operation.

| Design Standard | API 600/150 10434/AP160/15014313/ΑΡΙ 803 |

| Inspection & Testing Standard | API 598/150 5208 |

| Face to Face | As Per ANSI B 16.10 |

| End Connection | Flanged End To ANSI B16.5/85 10 Table PS/PN/DIN/15 Standard, Screwed End To ANSI 1.20.1 (B5J/NFT), Socket Weid End To ANSI 8 16.11. Buttweld End To ΑΝ Β 10.25 |

| Size Range | 1/2" Το 24" (DN15 Το DN600) (If higher sizes required, please do contact us) |

| Pressure Rating | #150, #300, #600, #800, #900, #1500 |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/As requested) |

Single-piece ball valves are durable and simple but limited in size. Two-piece valves allow easier maintenance and cover more sizes, while three-piece valves offer the easiest maintenance with modular parts but are more complex and expensive. Each type balances durability, ease of service, and application needs.

| Design Standard | Gate Valve - API 602 / ASME B 16.34 / ISO 15761 Standard Design Standard Globe Valve - BS 5352 / ASME B 16.34 / ISO 15761 Check Valve - BS 5352 / ASME B 16.34 / ISO 15761 Ball Valve - ISO 17292 / BS 5351 / BS 5159 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 / BS 5352 |

| End Connection | Screwed End To ANSI B 1.20.1 (BSP/NPT) Socket Weld End To ANSI B 16.11 Buttweld End To ANSI B 16.25 |

| Size Range | 1/4" Το 2" (DN6 Το DN50) (If higher sizes required, please do contact us) |

| Pressure Rating | #150, #300, #600, #800, #900, #1500 |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/As requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

The Stainless Steel Gate Valve (GGC Valve) offers durable, corrosion-resistant performance with a vertical gate mechanism for precise flow control. Its stainless steel construction ensures longevity and reliability in harsh environments. Ideal for applications requiring minimal maintenance and dependable operation.

| Design Standard | ASME B16.34 / Mfg. Std. |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | Mfg. Std. |

| End Connection | Screwed End To ANSI B 1.20.1 (BSP/NPT) Socket Weld End To ANSI B 16.11 |

| Size Range | 1/2" Το 4" (DN15 Το DN100) (If higher sizes required, please do contact us) |

| Pressure Rating | #150, #300, #600, #800, #900, #1500 /PN10/PN16 |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/As requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

The Forged Steel Gate Valve features robust construction for high-pressure and temperature applications, with a gate mechanism for precise flow control, ensuring durability and reliability in demanding industrial environments and offering long-lasting performance. Its design also allows for easy maintenance and operation.

| Design Standard | Gate Valve - API 602 / ASME B 16.34 / ISO 15761 Standard Design Standard Globe Valve - BS 5352 / ASME B 16.34 / ISO 15761 Check Valve - BS 5352 / ASME B 16.34 / ISO 15761 Ball Valve - ISO 17292 / BS 5351 / BS 5159 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 / BS 5352 |

| End Connection | Screwed End To ANSI B 1.20.1 (BSP/NPT) Socket Weld End To ANSI B 16.11 Buttweld End To ANSI B 16.25 |

| Size Range | 1/4" Το 2" (DN6 Το DN50) (If higher sizes required, please do contact us) |

| Pressure Rating | #150, #300, #600, #800, #900, #1500 |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/As requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

A bolted bonnet gate valve has a removable bonnet secured with bolts, enabling easy maintenance and repair. This design offers a strong, reliable seal for high-pressure and high-temperature applications. It’s commonly used in industries like oil and gas or water treatment, providing durability and straightforward servicing.

| Design Standard | API 600/150 10434/AP160/15014313/ΑΡΙ 803 |

| Inspection & Testing Standard | API 598/150 5208 |

| Face to Face | As Per ANSI B 16.10 |

| End Connection | Flanged End To ANSI B16.5/85 10 Table PS/PN/DIN/15 Standard, Screwed End To ANSI 1.20.1 (B5J/NFT), Socket Weid End To ANSI 8 16.11. Buttweld End To ΑΝ Β 10.25 |

| Size Range | 1/2" Το 24" (DN15 Το DN600) (If higher sizes required, please do contact us) |

| Pressure Rating | #150, #300, #600, #800, #900, #1500 |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/As requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |