High-performance plug valves engineered for precise flow control and exceptional durability.

Bellow sealed valves are designed to prevent leakage by using a metallic bellow, which forms a hermetic seal around the valve stem. These valves are especially effective in applications where zero leakage is critical, such as handling toxic or hazardous fluids. Bellow sealed valves are commonly used in industries like pharmaceuticals, petrochemicals, and nuclear energy, ensuring safe and reliable performance even in the most demanding environments.

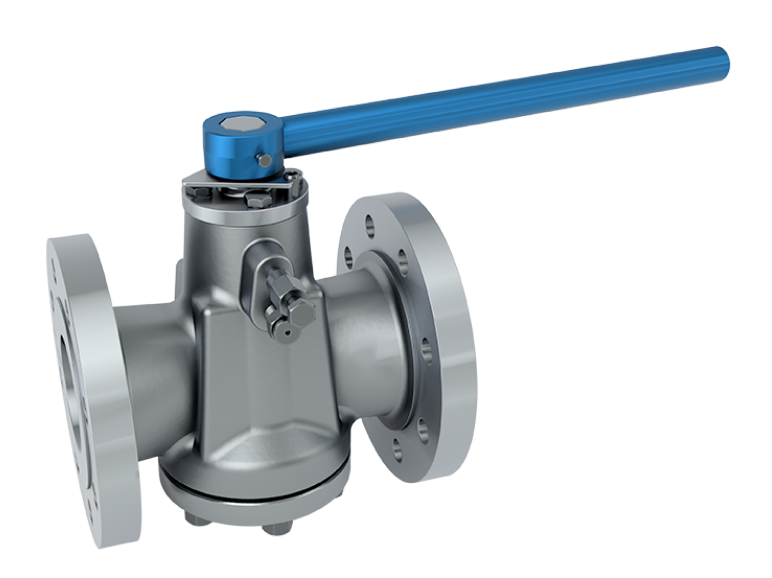

Non-lubricated plug valves operate without the need for sealing lubricants, relying instead on a mechanical sleeve or liner within the valve body. This design provides a low-maintenance, reliable solution for applications where contamination from lubricants must be avoided. Non-lubricated plug valves are suitable for handling gases, liquids, and slurries, commonly used in industries such as chemical processing, water treatment, and food & beverage, where cleanliness and ease of operation are essential.

Multi-port plug valves are designed to control the flow of fluids or gases through multiple inlet and outlet ports, allowing for efficient flow path selection and distribution within a single valve body. These valves eliminate the need for multiple valves in complex piping systems, simplifying design and reducing space requirements. Multi-port plug valves are commonly used in industries such as chemical processing, oil and gas, and water treatment, where managing multiple flow streams is critical to operational efficiency.

Lubricated plug valves are designed with a mechanism that uses a lubricant to create a sealing film between the plug and the valve body, ensuring smooth operation and effective sealing. This feature enhances the valve's longevity and reduces wear, making it ideal for applications involving abrasive or corrosive media. Lubricated plug valves are commonly used in industries such as oil and gas, petrochemicals, and water treatment, where reliable performance in demanding environments is essential.

Eccentric plug valves are designed with an offset plug, which creates a camming action as the valve opens and closes. This design reduces friction and wear, enhancing valve performance and lifespan. The eccentric action ensures a tight, bubble-tight seal, even in the presence of high pressures or abrasive media. Eccentric plug valves are commonly used in wastewater treatment, power generation, and industrial processes where dependable shutoff and throttling control are needed.