A Water Type Check Valve is tailored for water systems, using a disc or ball to permit flow in one direction and prevent backflow. It ensures reliable one-way flow control and minimizes reverse flow damage. Its design supports efficient water management with minimal resistance. Simple construction allows for easy installation and operation.

| Design Standard | Swing Check Valve - BS 1868, Lift Check Valve - BS 1868 / BS 5352 / DIN Std. Wafer Type Check Valve - API 6D, Disc Type Check Valve - DIN EN 558-2 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 / API 6D |

| End Connection | Flanged end to ANSI B 16.10 / BS 10 Flanged End To ANSI B 16.5/BS 10 Table JIS / PN / DIN / IS Standard : Screwed End To ANSI B 1.20.1 (BSP/NPT), Socket Weld End To ANSI B 16.11 Buttweld End To ANSI B 16.25, Wafer Type, Flangeless, Sandwich Type |

| Size Range | 1/2" Το 12" (DN15 Το DN600) (If higher sizes required, please do contact us) |

| Pressure Rating | #150, #300, #600, #800, #900, #1500 |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

Valve automation for seamless, efficient control and precision in your operations.

Valve automation involves equipping valves with electric, pneumatic, or hydraulic actuators to control their operation remotely and efficiently. This technology allows for precise, reliable, and real-time control of valve functions, enhancing operational efficiency and safety in complex systems. Automated valves are commonly used in industrial processes, water treatment, and energy sectors, where they streamline operations, reduce manual labor, and enable integration with broader control systems for optimized performance.

The Un-Lined Diaphragm Valve features a robust design without internal lining, making it suitable for less aggressive fluid handling. Its diaphragm mechanism ensures precise flow control and effective shutoff. Ideal for applications where lining is unnecessary, it offers reliable performance and ease of maintenance.

| Design Standard | BS EN 13397 (BS 5156) |

| Inspection & Testing Standard | BS EN 12266-1 ( BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | BS EN 13397 (BS 5156) |

| End Connection | Flanged End To ANSI B 16.5 / BS 10 Table D-E-F-H ; JIS/PN/DIN/ IS Standard |

| Size Range | 1/2" Το 8" (DN15 Το DN200) |

| Pressure Rating | PN10/150# |

| Operation | Hand Wheel / Pneumatic Actuator Operated |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

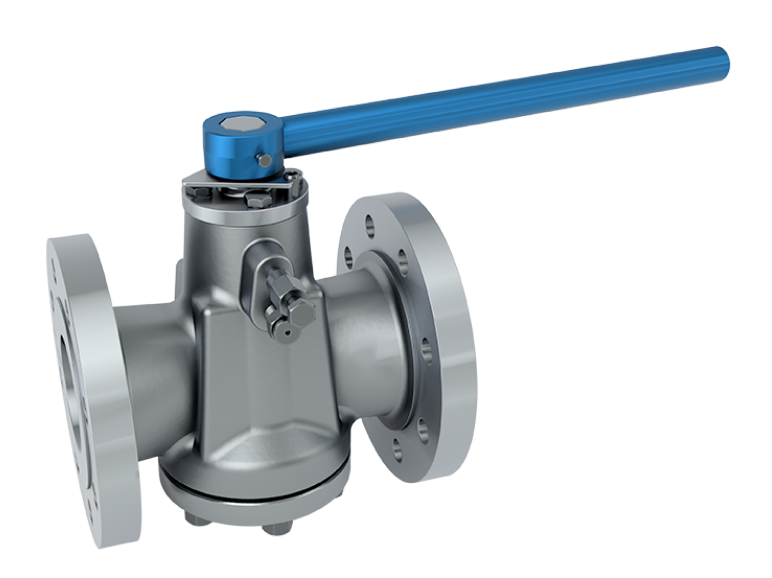

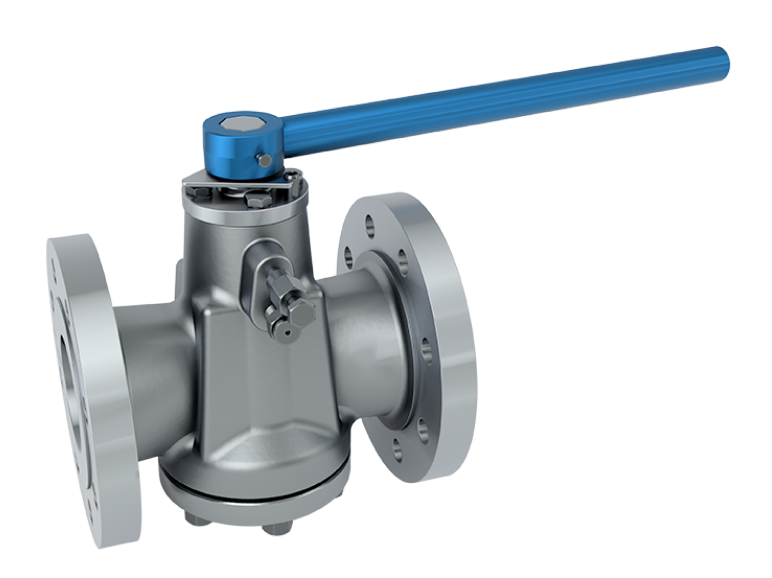

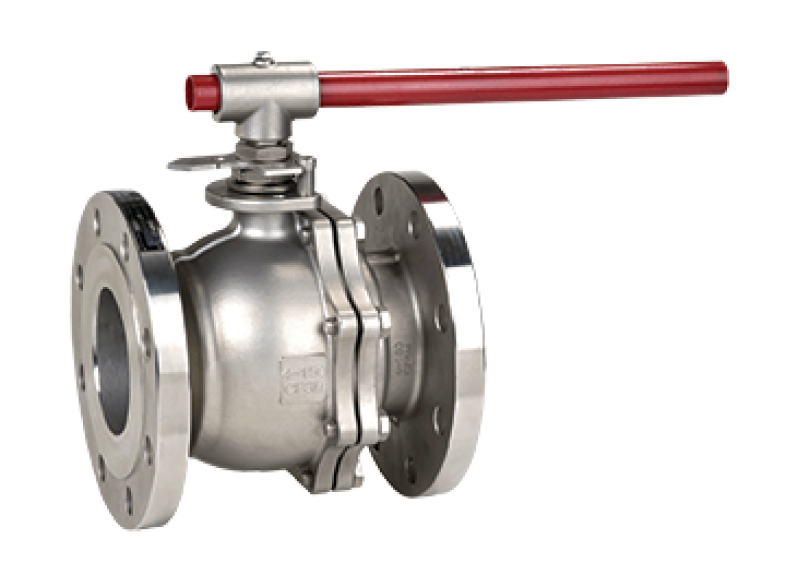

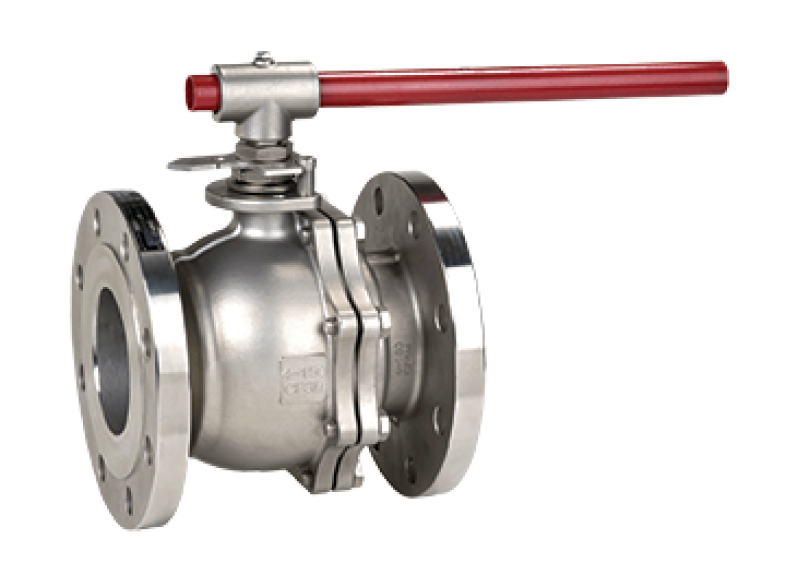

A trunnion ball valve features a ball supported by fixed trunnions, which stabilizes the ball and reduces operating torque. This design is ideal for high-pressure and high-temperature applications, offering reliable sealing and durability. It is commonly used in industries such as oil and gas, chemical processing, and power generation.

| Design Standard | BS 5159 / ISO 7121 / BS 5351 / ISO 17292 / API 6D / API 608 / ISO 14313 / ASME B 16.34 / BS EN 12516 |

| Inspection & Testing Standard | API 598 / API 6D / BS EN 12266 - 1 / ISO 5208 |

| Fire Testing | API 607 / ISO 10497 / BS EN 12266 - II |

| Face to Face | As Per ANSI B 16.10 |

| End Connection | Flanged End To ANSI B 16.5 / BS 10 Table D-E-F-H / JIS / PN / DIN / IS Standard Screwed End To ANSI B 1.20.1 (BSP/NPT) Socket Weld End To ANSI B 16.11 |

| Size Range | 50mm to 1000mm (If higher sizes required, please do contact us) |

| Pressure Rating | #150 / #300 / #600 / #800 / #900 / #1500 |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/as requested) |

| Port/Bore | Reduced or Full Bore |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

A Swing Type Check Valve utilizes a hinged disc that swings open to allow flow in one direction and closes to prevent backflow. This design ensures efficient and reliable one-way flow control, minimizing the risk of reverse flow damage. Its simple construction allows for easy installation and maintenance. Ideal for applications where backflow prevention is critical.

| Design Standard | Swing Check Valve - BS 1868, Lift Check Valve - BS 1868 / BS 5352 / DIN Std. Wafer Type Check Valve - API 6D, Disc Type Check Valve - DIN EN 558-2 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 / API 6D |

| End Connection | Flanged end to ANSI B 16.10 / BS 10 Flanged End To ANSI B 16.5/BS 10 Table JIS / PN / DIN / IS Standard : Screwed End To ANSI B 1.20.1 (BSP/NPT), Socket Weld End To ANSI B 16.11 Buttweld End To ANSI B 16.25, Wafer Type, Flangeless, Sandwich Type |

| Size Range | 1/2" Το 12" (DN15 Το DN600) (If higher sizes required, please do contact us) |

| Pressure Rating | 150, #300, #600, #800, #900, #1500 |

Stainless steel GGC valves for robust performance and corrosion resistance in demanding applications.

Stainless steel GGC valves are high-performance valves designed for demanding applications requiring exceptional durability and corrosion resistance. Made from high-grade stainless steel, these valves offer superior strength and reliability, even in harsh environments. They are ideal for use in industries such as chemical processing, oil and gas, and water treatment, where resistance to corrosion and extreme conditions is crucial. The robust construction ensures long service life and consistent performance, making them a dependable choice for critical applications.

| Design Standard | BS 5159 / ISO 7121 / BS 5351 / ISO 17292 / API 6D / ISO 14313 / ASME B 16.34 / BS EN 12516 |

| Inspection & Testing Standard | BS EN 12266 - 1 (BS 6755 - 1) / API 598 / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 / Mfg / Special on Request |

| End Connection | Flanged end to ANSI B 16.10 / BS 10 Table D-E-F-H / JIS / PN / DIN / IS Standard |

| Size Range | 1/2” x 1” To 6” x 10” (DN15 x DN25 To DN100 x DN250) |

| Pressure Rating | 150# / 300# |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

Special purpose valves designed for tailored solutions and unique operational needs.

Special purpose valves are intricately designed to tackle unique and demanding operational challenges that conventional valves may not address. These valves are engineered for specific requirements such as handling extreme pressures, high temperatures, or highly corrosive environments, making them ideal for specialized applications in industries like aerospace, pharmaceuticals, and advanced manufacturing. By providing precise control and reliable performance tailored to unique conditions, special purpose valves ensure optimal operation and safety in complex and critical scenarios.

The Slim-Seal Butterfly Valve features a compact design with a slim profile, making it ideal for tight spaces and limited installation areas. Its efficient sealing mechanism ensures reliable shutoff and minimal leakage. The valve's lightweight construction and straightforward operation provide ease of use and maintenance.

| Design Standard | BS 5155/ΑΡΙ 609 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | BS 5155/ΑΡΙ 609 |

| End Connection | Wafer, Flangeless, Sandwich Type End Connection Full Lug Type, Through or Tapped Hole Double Flanged End to |

| Size Range | 1-1/2" Το 48" (DN40 Το DN1200) (If higher sizes required, please do contact us) |

| Pressure Rating | PN10/PN16/150# |

| Operation | Hand Lever / Gear / Pneumatic / Electrical Actuator Operated (as applicable/as requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

Single-piece ball valves are durable and simple but limited in size. Two-piece valves allow easier maintenance and cover more sizes, while three-piece valves offer the easiest maintenance with modular parts but are more complex and expensive. Each type balances durability, ease of service, and application needs.

| Design Standard | BS 5159 / ISO 7121 / BS 5351 / ISO 17292 / API 6D / API 608 / ISO 14313 / ASME B 16.34 / BS EN 12516 |

| Inspection & Testing Standard | API 598 / API 6D / BS EN 12266 - 1 / ISO 5208 |

| Fire Testing | API 607 / ISO 10497 / BS EN 12266 - II |

| Face to Face | As Per ANSI B 16.10 |

| End Connection | Flanged End To ANSI B 16.5 / BS 10 Table D-E-F-H / JIS / PN / DIN / IS Standard Screwed End To ANSI B 1.20.1 (BSP/NPT) Socket Weld End To ANSI B 16.11 |

| Size Range | DN15 To DN50 (If higher sizes required, please do contact us) |

| Pressure Rating | 150# / 300# / 600# / 800# |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/as requested) |

| Port/Bore | Reduced or Full Bore |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

A Rising Stem Globe Valve has a stem that rises as the valve opens, providing a clear visual indication of its position. It offers precise flow control and is built for durability in high-pressure applications. The rising stem design ensures smooth operation and easy status monitoring. Its robust construction makes it ideal for demanding environments.

| Design Standard | BS 1873 / DIN Std. |

| Inspection & Testing Standard | BS EN 12266 I (BS 6755-1) / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 |

| End Connection | Flanged End To ANSI B 16.5/BS 10 Table, Screwed End To ANSI B 1.20.1 (BSP/NPT), Socket Weld End To ANSI B 16.11 Buttweld End To ANSI B 16.25 Table D-E-F-H / JIS / PN / DIN / IS Standard |

| Size Range | 1" Το 12" (DN25 Το DN300) (If higher sizes required, please do contact us) |

| Pressure Rating | 1150 / #300 / #600 / #800 / #900 / #1500 / PN 16 / PN25 / PN 40 |

| Operation | Hand Wheel / Gear / Electrical Actuator Operated (As applicable/as requested) |

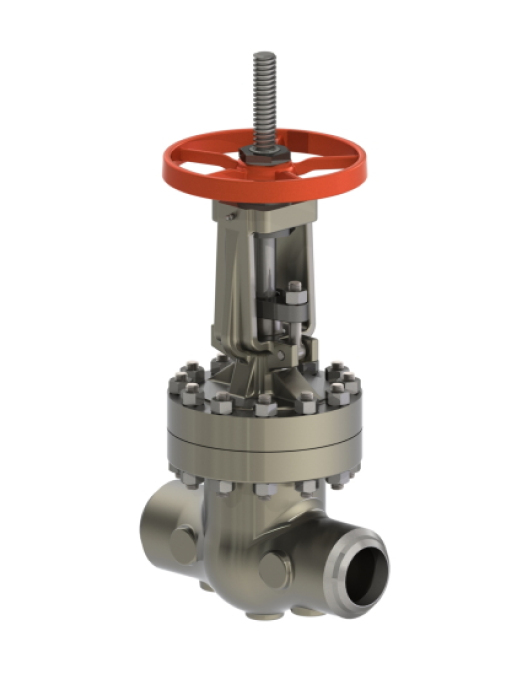

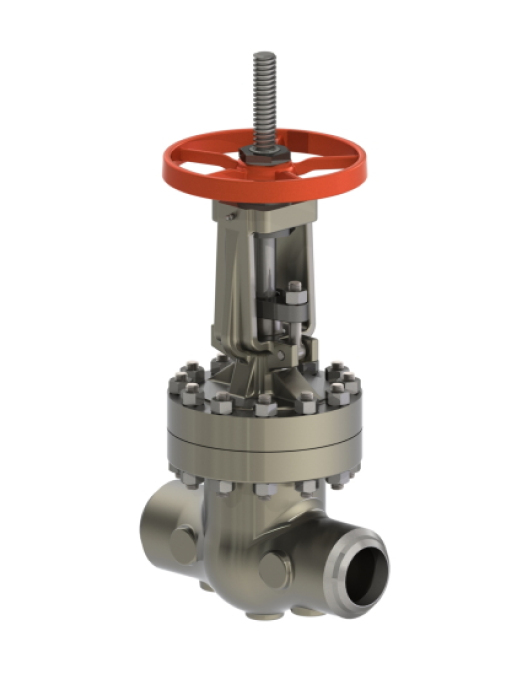

A rising stem gate valve has a stem that extends upward as the valve opens, offering clear visibility of the valve's position. This feature makes it easy to monitor the valve’s status and facilitates straightforward operation. Ideal for high-pressure and temperature applications, it ensures reliable performance and durability.

| Design Standard | API 600/150 10434/AP160/15014313/ΑΡΙ 803 |

| Inspection & Testing Standard | API 598/150 5208 |

| Face to Face | As Per ANSI B 16.10 |

| End Connection | Flanged End To ANSI B16.5/85 10 Table PS/PN/DIN/15 Standard, Screwed End To ANSI 1.20.1 (B5J/NFT), Socket Weid End To ANSI 8 16.11. Buttweld End To ΑΝ Β 10.25 |

| Size Range | 1/2" Το 24" (DN15 Το DN600) (If higher sizes required, please do contact us) |

| Pressure Rating | 150, #300, #600, #800, #900, #1500 |

| Operation | Hand Wheel/Gear Operated (As applicable/As requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

PTFE (FEP/PFA) lined valves for unmatched chemical resistance and durability.

PTFE (FEP/PFA) lined valves feature a protective lining made from fluoropolymer materials, such as PTFE, FEP, or PFA, to offer superior resistance to corrosive chemicals and high temperatures. The lining acts as a barrier between the media and the valve body, ensuring long-lasting performance in aggressive or harsh environments. These valves are ideal for use in chemical processing, pharmaceuticals, and other industries where chemical compatibility and reliable performance are critical. The PTFE lining also enhances the valve’s durability and reduces the risk of contamination.

The Pneumatic Jacketed Ball Valve features a pneumatic actuator for precise flow control and is equipped with a jacket for temperature regulation. This design ensures efficient operation and reliable performance in both high and low-temperature applications. Ideal for processes requiring temperature-sensitive handling, it integrates seamlessly into automated systems.

The Pneumatic Butterfly Valve uses a pneumatic actuator to control a disc mechanism, allowing precise and efficient flow regulation. Its compact design ensures quick operation and seamless integration into automated systems. Ideal for handling a variety of fluids, it offers reliable performance and durability.

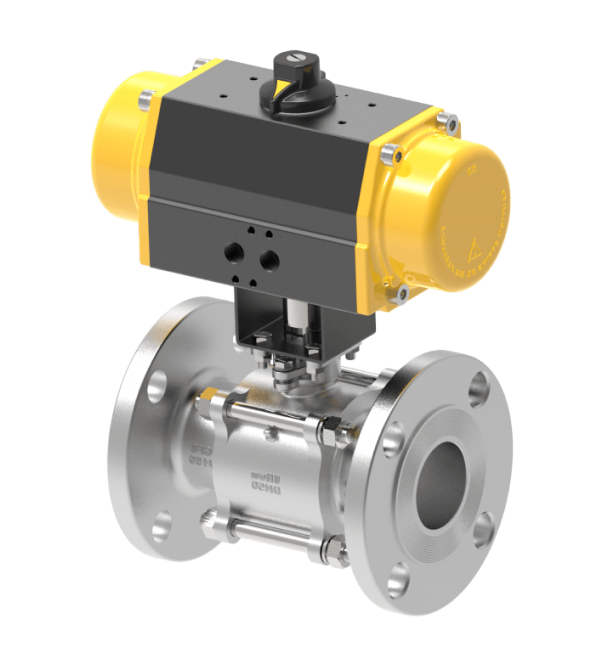

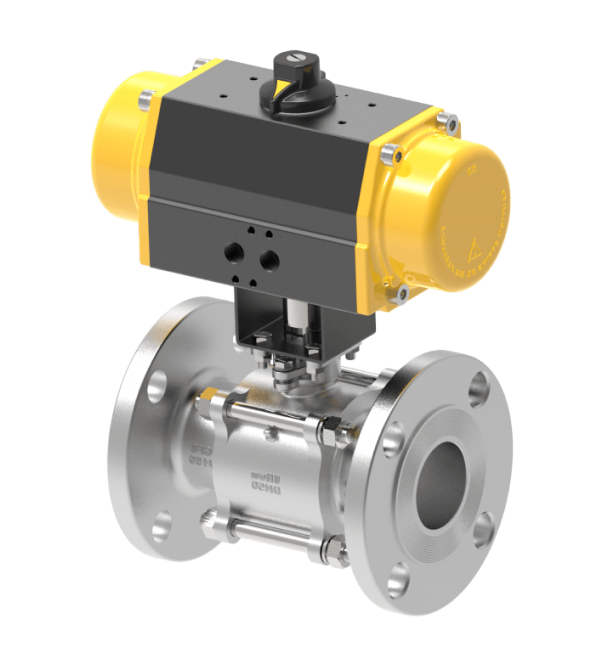

The Pneumatic Ball Valve uses a pneumatic actuator for precise and efficient control of the ball mechanism. It allows for quick, automated operation with minimal manual effort. Ideal for remote and automated systems, it ensures reliable performance. The valve's design promotes durability and seamless integration.

The Pneumatic 3-Way Valve features a pneumatic actuator that allows for precise control of flow between three ports. It enables efficient routing of fluids in various directions with quick and reliable operation. Ideal for applications requiring versatile flow control, it integrates seamlessly into automated systems.

High-performance plug valves engineered for precise flow control and exceptional durability.

Bellow sealed valves are designed to prevent leakage by using a metallic bellow, which forms a hermetic seal around the valve stem. These valves are especially effective in applications where zero leakage is critical, such as handling toxic or hazardous fluids. Bellow sealed valves are commonly used in industries like pharmaceuticals, petrochemicals, and nuclear energy, ensuring safe and reliable performance even in the most demanding environments.

An OS & Y (Outside Screw and Yoke) type globe valve is designed for precise flow control in piping systems. It features an external screw and yoke mechanism, which ensures accurate valve positioning and durability. The valve's stem rises as it opens, allowing for clear visibility of the valve's status.

| Design Standard | BS 1873 / DIN Std. |

| Inspection & Testing Standard | BS EN 12266 I (BS 6755-1) / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 |

| End Connection | Flanged End To ANSI B 16.5/BS 10 Table, Screwed End To ANSI B 1.20.1 (BSP/NPT), Socket Weld End To ANSI B 16.11 Buttweld End To ANSI B 16.25 Table D-E-F-H / JIS / PN / DIN / IS Standard |

| Size Range | 1" Το 12" (DN25 Το DN300) (If higher sizes required, please do contact us) |

| Pressure Rating | 1150 / #300 / #600 / #800 / #900 / #1500 / PN 16 / PN25 / PN 40 |

| Operation | Hand Wheel / Gear / Electrical Actuator Operated (As applicable/as requested) |

The OS & Y (Outside Stem and Yoke) gate valve has an external stem and yoke, allowing clear visibility of the valve's open or closed position. This design simplifies operation and maintenance while protecting the stem from the flow media. Ideal for high-pressure and temperature applications, it offers durability and easy access for operators.

| Design Standard | API 600/150 10434/AP160/15014313/ΑΡΙ 803 |

| Inspection & Testing Standard | API 598/150 5208 |

| Face to Face | As Per ANSI B 16.10 |

| End Connection | Flanged End To ANSI B16.5/85 10 Table PS/PN/DIN/15 Standard, Screwed End To ANSI 1.20.1 (B5J/NFT), Socket Weid End To ANSI 8 16.11. Buttweld End To ΑΝ Β 10.25 |

| Size Range | 1/2" Το 24" (DN15 Το DN600) (If higher sizes required, please do contact us) |

| Pressure Rating | #150, #300, #600, #800, #900, #1500 |

| Operation | Hand Wheel/Gear Operated (As applicable/As requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

The Offset Disc Butterfly Valve features an offset disc design that reduces friction and wear, ensuring smooth operation and long-term durability. This design allows for precise flow control and effective sealing, making it ideal for handling various fluids. Its compact structure simplifies installation and maintenance.

| Design Standard | BS 5155/ΑΡΙ 609 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | BS 5155/ΑΡΙ 609 |

| End Connection | Wafer, Flangeless, Sandwich Type End Connection Full Lug Type, Through or Tapped Hole Double Flanged End to |

| Size Range | 1-1/2" Το 48" (DN40 Το DN1200) (If higher sizes required, please do contact us) |

| Pressure Rating | PN10/PN16/150# |

| Operation | Hand Lever / Gear / Pneumatic / Electrical Actuator Operated (as applicable/as requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

Non-lubricated plug valves operate without the need for sealing lubricants, relying instead on a mechanical sleeve or liner within the valve body. This design provides a low-maintenance, reliable solution for applications where contamination from lubricants must be avoided. Non-lubricated plug valves are suitable for handling gases, liquids, and slurries, commonly used in industries such as chemical processing, water treatment, and food & beverage, where cleanliness and ease of operation are essential.

Multiport ball valves for versatile flow management and efficient fluid distribution.

Multiport ball valves are versatile flow control devices that feature multiple ports, allowing them to direct flow to various paths within a system. Their design enables efficient fluid distribution and switching between multiple pipelines with a single valve, streamlining complex operations. Ideal for applications requiring flow diversion, mixing, or splitting, multiport ball valves offer compact solutions for managing fluid dynamics and enhancing system flexibility. Their ease of operation and reduced need for additional valves make them a cost-effective choice for optimizing flow management.

| Design Standard | BS 5159/ISO 7121 / BS 5351 / ISO 17292 / API 6D / ISO 14313/ASME B 16.34 / BS EN 12516 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | Mfg. Std. |

| End Connection | Flanged End To ANSI B 16.5 / BS 10 Table D-E-F-H JIS/PN/DIN/ IS Standard; Screwed End To ANSI B 1.20.1 (BSP/NPT) |

| Size Range | 1/2" Το 12" (DN15 Το DN300) (If higher sizes required, please do contact us) |

| Pressure Rating | 150# / 300# |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/as requested) |

| Port/Bore | Reduced or Full Bore |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

Multi-port plug valves are designed to control the flow of fluids or gases through multiple inlet and outlet ports, allowing for efficient flow path selection and distribution within a single valve body. These valves eliminate the need for multiple valves in complex piping systems, simplifying design and reducing space requirements. Multi-port plug valves are commonly used in industries such as chemical processing, oil and gas, and water treatment, where managing multiple flow streams is critical to operational efficiency.

Lubricated plug valves are designed with a mechanism that uses a lubricant to create a sealing film between the plug and the valve body, ensuring smooth operation and effective sealing. This feature enhances the valve's longevity and reduces wear, making it ideal for applications involving abrasive or corrosive media. Lubricated plug valves are commonly used in industries such as oil and gas, petrochemicals, and water treatment, where reliable performance in demanding environments is essential.

A Lift Type Check Valve features a vertically moving disc or plug that lifts off its seat to allow flow in one direction and drops back to prevent backflow. Its design ensures effective one-way flow control with minimal pressure drop. Ideal for applications requiring reliable backflow prevention and smooth flow management.

| Design Standard | Swing Check Valve - BS 1868, Lift Check Valve - BS 1868 / BS 5352 / DIN Std. Wafer Type Check Valve - API 6D, Disc Type Check Valve - DIN EN 558-2 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 / API 6D |

| End Connection | Flanged end to ANSI B 16.10 / BS 10 Flanged End To ANSI B 16.5/BS 10 Table JIS / PN / DIN / IS Standard : Screwed End To ANSI B 1.20.1 (BSP/NPT), Socket Weld End To ANSI B 16.11 Buttweld End To ANSI B 16.25, Wafer Type, Flangeless, Sandwich Type |

| Size Range | 1/2" Το 12" (DN15 Το DN600) (If higher sizes required, please do contact us) |

| Pressure Rating | #150, #300, #600, #800, #900, #1500 |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

Jacketed ball valves for reliable flow control and thermal protection in extreme conditions.

Jacketed ball valves are designed to handle extreme temperature conditions by incorporating a surrounding jacket that maintains or adjusts the temperature of the media flowing through the valve. This design ensures reliable performance and prevents issues like freezing or overheating, making them ideal for processes that require consistent thermal management and robust flow control in demanding industrial environments. Their construction also enhances safety by preventing thermal shock and protecting against thermal stress.

| Design Standard | BS 5159/ISO 7121 / BS 5351 / ISO 17292/ API 6D / ISO 14313 / ASME B 16.34 / BS EN 12516 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 / Mfg. Std. / Special on request |

| End Connection | Flanged End To ANSI B 16.5 / BS 10 Table D-E-F-H/JIS/PN/ DIN / IS Standard |

| Size Range | 1/2" x 1" Το 6" x 10" (DN15 x DN25 Το DN100 x DN250) (If higher sizes required, please do contact us) |

| Pressure Rating | 150# / 300# |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/as requested) |

| Port/Bore | Reduced or Full Bore |

The High Pressure Ball Valve is designed to handle fluids at elevated pressures, providing robust performance and reliable flow control. Its durable construction ensures safe operation under demanding conditions. The ball mechanism allows for precise regulation and quick shutoff.

The Hard Rubber Lined Diaphragm Valve features a durable rubber lining that protects against corrosion and abrasion, ensuring long-lasting performance. Its diaphragm mechanism provides precise flow control and effective sealing. Ideal for handling aggressive fluids, the valve's design allows for reliable operation and easy maintenance.

| Design Standard | BS EN 13397 (BS 5156) |

| Inspection & Testing Standard | BS EN 12266-1 ( BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | BS EN 13397 (BS 5156) |

| End Connection | Flanged End To ANSI B 16.5 / BS 10 Table D-E-F-H ; JIS/PN/DIN/ IS Standard |

| Size Range | 1/2" Το 8" (DN15 Το DN200) |

| Pressure Rating | PN10/150# |

| Operation | Hand Wheel / Pneumatic Actuator Operated |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

A half jacket ball valve has a partial jacket around the valve body to control fluid temperature, preventing issues like freezing or solidification. This design is ideal for applications requiring temperature management, such as in chemical processing or food production. It combines efficient flow control with effective temperature regulation.

| Design Standard | BS 5159 / ISO 7121 / BS 5351 / ISO 17292 / API 6D / ISO 14313 / ASME B 16.34 / BS EN 12516 |

| Inspection & Testing Standard | BS EN 12266 - 1 (BS 6755 - 1) / API 598 / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 / Mfg / Special on Request |

| End Connection | Flanged end to ANSI B 16.10 / BS 10 Table D-E-F-H / JIS / PN / DIN / IS Standard |

| Size Range | 1/2” x 1” To 6” x 10” (DN15 x DN25 To DN100 x DN250) (If higher sizes required, please do contact us) |

| Pressure Rating | 150# / 300# |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/as requested) |

| Port/Bore | Reduced or Full Bore |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

Globe valves for precise flow regulation and fine-tuned control in complex systems.

Globe valves are precision control devices designed to regulate flow by varying the size of the flow passage. They feature a spherical body with an internal baffle that moves to throttle the flow, allowing for fine-tuned control and stable flow regulation. Ideal for applications requiring accurate flow adjustment and frequent operation, globe valves provide excellent shut-off capabilities and are widely used in systems where precise flow control is crucial. Their design ensures minimal turbulence and reliable performance across a range of pressures and temperatures.

| Design Standard | BS 1873 / DIN Std. |

| Inspection & Testing Standard | BS EN 12266 I (BS 6755-1) / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 |

| End Connection | Flanged End To ANSI B 16.5/BS 10 Table, Screwed End To ANSI B 1.20.1 (BSP/NPT), Socket Weld End To ANSI B 16.11 Buttweld End To ANSI B 16.25 Table D-E-F-H / JIS / PN / DIN / IS Standard |

| Size Range | 1" Το 12" (DN25 Το DN300) (If higher sizes required, please do contact us) |

| Pressure Rating | #150 / #300 / #600 / #800 / #900 / #1500 / PN 16 / PN25 / PN 40 |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/as requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

The Stainless Steel Globe Valve (GGC Valve) provides precise flow control with a durable stainless steel construction. Its linear motion mechanism allows accurate adjustment of flow rates. Designed for reliability and minimal maintenance in harsh environments. Ideal for applications requiring long-lasting performance.

| Design Standard | ASME B16.34 / Mfg. Std. |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | Mfg. Std. |

| End Connection | Screwed End To ANSI B 1.20.1 (BSP/NPT) Socket Weld End To ANSI B 16.11 |

| Size Range | 1/2" Το 4" (DN15 Το DN100) (If higher sizes required, please do contact us) |

| Operation | Hand Wheel / Gear / Electrical Actuator Operated (As applicable/as requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

The Forged Steel Globe Valve provides precise flow control with durable forged steel construction, ideal for high-pressure and high-temperature applications. Its globe mechanism ensures accurate flow regulation and long-lasting performance. Designed for reliability and easy maintenance in demanding industrial environments.

| Design Standard | Gate Valve - API 602 / ASME B 16.34 / ISO 15761 Standard Design Standard Globe Valve - BS 5352 / ASME B 16.34 / ISO 15761 Check Valve - BS 5352 / ASME B 16.34 / ISO 15761 Ball Valve - ISO 17292 / BS 5351 / BS 5159 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 / BS 5352 |

| End Connection | Screwed End To ANSI B 1.20.1 (BSP/NPT) Socket Weld End To ANSI B 16.11 Buttweld End To ANSI B 16.25 |

| Size Range | 1/4" Το 2" (DN6 Το DN50) (If higher sizes required, please do contact us) |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/as requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

The Globe Control Valve uses a linear motion mechanism to precisely regulate fluid flow and pressure. Its design allows for accurate control and adjustment, making it ideal for complex process systems. The valve’s robust construction ensures reliable performance and durability. It is well-suited for applications requiring fine-tuned flow control and minimal maintenance.

Gate valves are robust on/off control devices designed to provide a full, unobstructed flow path when fully open, making them ideal for applications where minimal pressure drop is essential. They operate by lifting a gate or disc out of the flow path, ensuring a tight seal when closed to prevent leakage. Gate valves are commonly used in high-pressure and high-temperature applications where reliable isolation is critical, offering durability and straightforward operation.

| Design Standard | API 600/150 10434/AP160/15014313/ΑΡΙ 803 |

| Inspection & Testing Standard | API 598/150 5208 |

| Face to Face | As Per ANSI B 16.10 |

| End Connection | Flanged End To ANSI B16.5/85 10 Table PS/PN/DIN/15 Standard, Screwed End To ANSI 1.20.1 (B5J/NFT), Socket Weid End To ANSI 8 16.11. Buttweld End To ΑΝ Β 10.25 |

| Size Range | 1/2" Το 24" (DN15 Το DN600) (If higher sizes required, please do contact us) |

| Pressure Rating | #150, #300, #600, #800, #900, #1500 |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/As requested) |

Single-piece ball valves are durable and simple but limited in size. Two-piece valves allow easier maintenance and cover more sizes, while three-piece valves offer the easiest maintenance with modular parts but are more complex and expensive. Each type balances durability, ease of service, and application needs.

| Design Standard | Gate Valve - API 602 / ASME B 16.34 / ISO 15761 Standard Design Standard Globe Valve - BS 5352 / ASME B 16.34 / ISO 15761 Check Valve - BS 5352 / ASME B 16.34 / ISO 15761 Ball Valve - ISO 17292 / BS 5351 / BS 5159 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 / BS 5352 |

| End Connection | Screwed End To ANSI B 1.20.1 (BSP/NPT) Socket Weld End To ANSI B 16.11 Buttweld End To ANSI B 16.25 |

| Size Range | 1/4" Το 2" (DN6 Το DN50) (If higher sizes required, please do contact us) |

| Pressure Rating | #150, #300, #600, #800, #900, #1500 |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/As requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

The Stainless Steel Gate Valve (GGC Valve) offers durable, corrosion-resistant performance with a vertical gate mechanism for precise flow control. Its stainless steel construction ensures longevity and reliability in harsh environments. Ideal for applications requiring minimal maintenance and dependable operation.

| Design Standard | ASME B16.34 / Mfg. Std. |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | Mfg. Std. |

| End Connection | Screwed End To ANSI B 1.20.1 (BSP/NPT) Socket Weld End To ANSI B 16.11 |

| Size Range | 1/2" Το 4" (DN15 Το DN100) (If higher sizes required, please do contact us) |

| Pressure Rating | #150, #300, #600, #800, #900, #1500 /PN10/PN16 |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/As requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

The Forged Steel Gate Valve features robust construction for high-pressure and temperature applications, with a gate mechanism for precise flow control, ensuring durability and reliability in demanding industrial environments and offering long-lasting performance. Its design also allows for easy maintenance and operation.

| Design Standard | Gate Valve - API 602 / ASME B 16.34 / ISO 15761 Standard Design Standard Globe Valve - BS 5352 / ASME B 16.34 / ISO 15761 Check Valve - BS 5352 / ASME B 16.34 / ISO 15761 Ball Valve - ISO 17292 / BS 5351 / BS 5159 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 / BS 5352 |

| End Connection | Screwed End To ANSI B 1.20.1 (BSP/NPT) Socket Weld End To ANSI B 16.11 Buttweld End To ANSI B 16.25 |

| Size Range | 1/4" Το 2" (DN6 Το DN50) (If higher sizes required, please do contact us) |

| Pressure Rating | #150, #300, #600, #800, #900, #1500 |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/As requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

A full jacket ball valve has a jacket that completely surrounds the valve body, providing uniform temperature control. This design helps maintain consistent fluid temperatures and prevents issues like freezing or crystallization. It is ideal for applications in chemical processing and food production.

| Design Standard | BS 5159 / ISO 7121 / BS 5351 / ISO 17292 / API 6D / ISO 14313 / ASME B 16.34 / BS EN 12516 |

| Inspection & Testing Standard | BS EN 12266 - 1 (BS 6755 - 1) / API 598 / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 / Mfg / Special on Request |

| End Connection | Flanged end to ANSI B 16.10 / BS 10 Table D-E-F-H / JIS / PN / DIN / IS Standard |

| Size Range | 1/2” x 1” To 6” x 10” (DN15 x DN25 To DN100 x DN250) (If higher sizes required, please do contact us) |

| Pressure Rating | 150# / 300# |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/as requested) |

| Port/Bore | Reduced or Full Bore |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

Forged steel valves for exceptional strength, durability, and reliability in high-pressure environments.

Forged steel valves are engineered for high-pressure and high-temperature applications, offering exceptional strength and durability. Made from forged steel, these valves are known for their robust construction and resistance to mechanical stress and fatigue. Their design ensures reliable performance in demanding environments, such as oil and gas, power generation, and chemical processing. Forged steel valves provide excellent sealing capabilities and long-lasting service, making them a preferred choice for critical industrial operations.

| Design Standard | BS 5159 / ISO 7121 / BS 5351 / ISO 17292 / API 6D / ISO 14313 / ASME B 16.34 / BS EN 12516 |

| Inspection & Testing Standard | BS EN 12266 - 1 (BS 6755 - 1) / API 598 / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 / Mfg / Special on Request |

| End Connection | Flanged end to ANSI B 16.10 / BS 10 Table D-E-F-H / JIS / PN / DIN / IS Standard |

| Size Range | 1/2” x 1” To 6” x 10” (DN15 x DN25 To DN100 x DN250) |

| Pressure Rating | 150# / 300# |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

Floating ball valves have a ball that is not fixed but floats within the valve body, relying on fluid pressure to create a tight seal against the downstream seat when closed. This design ensures reliable sealing and simple operation. Ideal for various applications including water, oil, and gas, they effectively handle pressure changes and offer ease of maintenance.

| Design Standard | BS 5159 / ISO 7121 / BS 5351 / ISO 17292 / API 6D / API 608 / ISO 14313 / ASME B 16.34 / BS EN 12516 |

| Inspection & Testing Standard | API 598 / API 6D / BS EN 12266 - 1 / ISO 5208 |

| Fire Testing | API 607 / ISO 10497 / BS EN 12266 - II |

| Face to Face | As Per ANSI B 16.10 |

| End Connection | Flanged End To ANSI B 16.5 / BS 10 Table D-E-F-H / JIS / PN / DIN / IS Standard Screwed End To ANSI B 1.20.1 (BSP/NPT) Socket Weld End To ANSI B 16.11 |

| Size Range | 1/4’’ To 12’’ DN6 To DN300 (If higher sizes required, please do contact us) |

| Pressure Rating | 150# / 300# / 600# / 800# |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/as requested) |

| Port/Bore | Reduced or Full Bore |

| Type of Construction | 2 piece or 3 piece |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

The Flange Mounted Sight Glass allows for visual inspection of fluid flow within a pipeline through its clear viewing window. Its flange mounting ensures secure and stable installation in various piping systems. Ideal for monitoring flow conditions and detecting potential issues, it provides ease of maintenance and integration.

The Extended Stem Ball Valve features an extended stem design that allows for easy operation in high-temperature or elevated installations. Its ball mechanism ensures precise flow control and reliable performance. The extended stem provides accessibility for valve operation in challenging environments.

The Extended Stem 3-Way Ball Valve features a long stem for easy operation in high or elevated installations, allowing versatile flow control between three ports. Its ball mechanism ensures precise flow regulation and reliable switching. Ideal for applications requiring remote or hard-to-reach operation, it provides durable performance and ease of maintenance.

The Electrical Actuated Butterfly Valve features an electric actuator for precise and automated control of the disc mechanism, ensuring efficient flow regulation. Its design allows for quick and reliable valve operation, suitable for integration into automated systems. Built for durability and performance, it is ideal for handling a variety of fluids.

Eccentric plug valves are designed with an offset plug, which creates a camming action as the valve opens and closes. This design reduces friction and wear, enhancing valve performance and lifespan. The eccentric action ensures a tight, bubble-tight seal, even in the presence of high pressures or abrasive media. Eccentric plug valves are commonly used in wastewater treatment, power generation, and industrial processes where dependable shutoff and throttling control are needed.

A Disc Type Check Valve uses a disc that tilts or swings to allow flow in one direction and closes to prevent backflow. Its design ensures effective one-way flow control with minimal resistance. The valve provides reliable backflow prevention and maintains efficient flow in various applications. Simple construction allows for easy installation and maintenance.

| Design Standard | Swing Check Valve - BS 1868, Lift Check Valve - BS 1868 / BS 5352 / DIN Std. Wafer Type Check Valve - API 6D, Disc Type Check Valve - DIN EN 558-2 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 / API 6D |

| End Connection | Flanged end to ANSI B 16.10 / BS 10 Flanged End To ANSI B 16.5/BS 10 Table JIS / PN / DIN / IS Standard : Screwed End To ANSI B 1.20.1 (BSP/NPT), Socket Weld End To ANSI B 16.11 Buttweld End To ANSI B 16.25, Wafer Type, Flangeless, Sandwich Type |

| Size Range | 1/2" Το 12" (DN15 Το DN600) (If higher sizes required, please do contact us) |

| Pressure Rating | #150, #300, #600, #800, #900, #1500 |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

Diaphragm valves for precise, leak-free control and excellent sealing in diverse applications.

Diaphragm valves are precision control valves that use a flexible diaphragm to regulate flow by varying the size of the flow passage. When actuated, the diaphragm moves to either open or close the flow path, providing a tight seal and effectively preventing leakage. Ideal for applications involving corrosive, abrasive, or sanitary fluids, diaphragm valves offer reliable isolation and control while minimizing contact between the media and the valve body. Their design ensures smooth, reliable operation and is well-suited for industries such as pharmaceuticals, food and beverage, and chemical processing.

| Design Standard | BS EN 13397 (BS 5156) |

| Inspection & Testing Standard | BS EN 12266-1 ( BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | BS EN 13397 (BS 5156) |

| End Connection | Flanged End To ANSI B 16.5 / BS 10 Table D-E-F-H ; JIS/PN/DIN/ IS Standard |

| Size Range | 1/2" Το 8" (DN15 Το DN200) |

| Pressure Rating | PN10/150# |

| Operation | Hand Wheel / Pneumatic Actuator Operated |

Single-piece ball valves are durable and simple but limited in size. Two-piece valves allow easier maintenance and cover more sizes, while three-piece valves offer the easiest maintenance with modular parts but are more complex and expensive. Each type balances durability, ease of service, and application needs.

| Design Standard | BS EN 13397 (BS 5156) |

| Inspection & Testing Standard | BS EN 12266-1 ( BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | BS EN 13397 (BS 5156) |

| End Connection | Flanged End To ANSI B 16.5 / BS 10 Table D-E-F-H ; JIS/PN/DIN/ IS Standard |

| Size Range | 1/2" Το 8" (DN15 Το DN200) |

| Pressure Rating | PN10/150# |

| Operation | Hand Wheel / Pneumatic Actuator Operated |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

The Diaphragm Control Valve features a flexible diaphragm that provides precise regulation of fluid flow and pressure. Its design ensures effective sealing and control, making it suitable for handling various fluids in complex systems. The valve’s construction supports reliable performance and easy maintenance.

Control valves for accurate flow regulation and optimal system performance.

Control valves are crucial in industrial systems for regulating the flow, pressure, temperature, or level of fluids by adjusting the valve’s position based on control signals. These valves are equipped with actuators and positioners that respond to inputs from sensors and control systems, enabling precise adjustments to optimize process parameters. By maintaining stable and efficient operation, control valves play a key role in enhancing system performance, safety, and reliability across diverse applications such as chemical processing, water treatment, and energy production.

Single-piece ball valves are durable and simple but limited in size. Two-piece valves allow easier maintenance and cover more sizes, while three-piece valves offer the easiest maintenance with modular parts but are more complex and expensive. Each type balances durability, ease of service, and application needs.

| Design Standard | ASME B16.34 / Mfg. Std. |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | Mfg. Std. |

| End Connection | Screwed End To ANSI B 1.20.1 (BSP/NPT) Socket Weld End To ANSI B 16.11 |

| Size Range | 1/2" Το 12" (DN15 Το DN600) (If higher sizes required, please do contact us) |

| Pressure Rating | #150, #300, #600, #800, #900, #1500 |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

The Center Disc Butterfly Valve uses a centrally positioned disc to regulate flow with precise control and minimal pressure drop. Its compact design allows for easy installation and maintenance, making it suitable for diverse fluid handling applications. The valve ensures reliable performance and efficient shutoff in various industrial environments.

| Design Standard | BS 5155/ΑΡΙ 609 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | BS 5155/ΑΡΙ 609 |

| End Connection | Wafer, Flangeless, Sandwich Type End Connection Full Lug Type, Through or Tapped Hole Double Flanged End to |

| Size Range | 1-1/2" Το 48" (DN40 Το DN1200) (If higher sizes required, please do contact us) |

| Pressure Rating | PN10/PN16/150# |

| Operation | Hand Lever / Gear / Pneumatic / Electrical Actuator Operated (as applicable/as requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

Butterfly valves for compact, efficient flow control with minimal pressure drop.

Butterfly valves are compact and efficient flow control devices characterized by a rotating disc or vane that regulates fluid flow through the valve. When the valve is turned, the disc pivots to open or close the flow path, allowing for quick and precise flow control. Their streamlined design minimizes pressure drop and space requirements, making them ideal for applications in various industries such as water treatment, HVAC systems, and process control. Butterfly valves offer a reliable and cost-effective solution for managing fluid flow in both large and small diameter pipelines.

| Design Standard | BS 5155/ΑΡΙ 609 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | BS 5155/ΑΡΙ 609 |

| End Connection | Wafer, Flangeless, Sandwich Type End Connection Full Lug Type, Through or Tapped Hole Double Flanged End to |

| Size Range | 1-1/2" Το 48" (DN40 Το DN1200) (If higher sizes required, please do contact us) |

| Pressure Rating | PN10/PN16/150# |

| Operation | Hand Lever / Gear / Pneumatic / Electrical Actuator Operated (as applicable/as requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

Single-piece ball valves are durable and simple but limited in size. Two-piece valves allow easier maintenance and cover more sizes, while three-piece valves offer the easiest maintenance with modular parts but are more complex and expensive. Each type balances durability, ease of service, and application needs.

| Design Standard | BS 5155/ΑΡΙ 609 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | BS 5155/ΑΡΙ 609 |

| End Connection | Wafer, Flangeless, Sandwich Type End Connection Full Lug Type, Through or Tapped Hole Double Flanged End to |

| Size Range | 1-1/2" Το 48" (DN40 Το DN1200) (If higher sizes required, please do contact us) |

| Pressure Rating | PN10/PN16/150# |

| Operation | Hand Lever / Gear / Pneumatic / Electrical Actuator Operated (as applicable/as requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

The Butterfly Control Valve features a disc mechanism that allows for precise flow regulation and efficient control of fluid flow. Its compact design provides easy installation and integration into various systems. Ideal for managing a range of fluids, it ensures reliable performance and quick response.

A bolted bonnet globe valve features a bonnet secured with bolts, providing easy access for maintenance and repair. It offers reliable sealing and precise flow control, ideal for high-pressure and high-temperature conditions. The robust design ensures durability and consistent performance.

| Design Standard | BS 1873 / DIN Std. |

| Inspection & Testing Standard | BS EN 12266 I (BS 6755-1) / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 |

| End Connection | Flanged End To ANSI B 16.5/BS 10 Table, Screwed End To ANSI B 1.20.1 (BSP/NPT), Socket Weld End To ANSI B 16.11 Buttweld End To ANSI B 16.25 Table D-E-F-H / JIS / PN / DIN / IS Standard |

| Size Range | 1" Το 12" (DN25 Το DN300) (If higher sizes required, please do contact us) |

| Pressure Rating | 1150 / #300 / #600 / #800 / #900 / #1500 / PN 16 / PN25 / PN 40 |

| Operation | Hand Wheel / Gear / Electrical Actuator Operated (As applicable/as requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

A bolted bonnet gate valve has a removable bonnet secured with bolts, enabling easy maintenance and repair. This design offers a strong, reliable seal for high-pressure and high-temperature applications. It’s commonly used in industries like oil and gas or water treatment, providing durability and straightforward servicing.

| Design Standard | API 600/150 10434/AP160/15014313/ΑΡΙ 803 |

| Inspection & Testing Standard | API 598/150 5208 |

| Face to Face | As Per ANSI B 16.10 |

| End Connection | Flanged End To ANSI B16.5/85 10 Table PS/PN/DIN/15 Standard, Screwed End To ANSI 1.20.1 (B5J/NFT), Socket Weid End To ANSI 8 16.11. Buttweld End To ΑΝ Β 10.25 |

| Size Range | 1/2" Το 24" (DN15 Το DN600) (If higher sizes required, please do contact us) |

| Pressure Rating | #150, #300, #600, #800, #900, #1500 |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/As requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

Bellow seal Y-type valves are specialized valves designed to provide a leak-tight seal between the valve body and the plug. They feature a flexible bellows element that surrounds the valve stem, creating a reliable and durable seal even under harsh conditions. These valves are commonly used in applications where precise control of fluid flow is required.

Multiport ball valves for versatile flow management and efficient fluid distribution.

Below seal valves are specialized valves designed to operate in environments where the fluid being controlled is under high pressure or temperature. These valves have a unique construction that incorporates a sealing element positioned below the valve body, providing enhanced protection against leakage and corrosion. They are commonly used in industries such as oil and gas, chemical processing, and power generation, where demanding conditions necessitate robust and reliable valve solutions.

Bellow seal globe valves are specialized valves designed to provide a leak-tight seal between the valve stem and the body. They feature a flexible bellows element that surrounds the stem, creating a reliable and durable seal even under harsh conditions. These valves are commonly used in applications where precise control of fluid flow is essential.

Bellow seal gate valves are specialized valves designed to provide a leak-tight seal between the valve body and the gate. They feature a flexible bellows element that surrounds the valve stem, creating a reliable and durable seal even under harsh conditions. These valves are commonly used in applications where complete isolation of fluid flow is required.

Bellow seal control valves are specialized valves designed to provide precise and accurate control of fluid flow. They feature a flexible bellows element that surrounds the valve stem, creating a reliable and leak-tight seal. These valves are commonly used in applications where precise regulation of fluid flow is critical.

Single-piece ball valves are durable and simple but limited in size. Two-piece valves allow easier maintenance and cover more sizes, while three-piece valves offer the easiest maintenance with modular parts but are more complex and expensive. Each type balances durability, ease of service, and application needs.

| Design Standard | Gate Valve - API 602 / ASME B 16.34 / ISO 15761 Standard Design Standard Globe Valve - BS 5352 / ASME B 16.34 / ISO 15761 Check Valve - BS 5352 / ASME B 16.34 / ISO 15761 Ball Valve - ISO 17292 / BS 5351 / BS 5159 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 / BS 5352 |

| End Connection | Screwed End To ANSI B 1.20.1 (BSP/NPT) Socket Weld End To ANSI B 16.11 Buttweld End To ANSI B 16.25 |

| Size Range | 1/4" Το 2" (DN6 Το DN50) (If higher sizes required, please do contact us) |

| Pressure Rating | 800# / 1500# |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/as requested) |

| Port/Bore | Reduced or Full Bore |

The Forged Steel Ball Valve features a robust construction designed for high-pressure and high-temperature applications. Its ball mechanism allows for quick and precise flow control with a simple quarter-turn operation. Durable and reliable, it ensures long-term performance in demanding environments. The valve’s design also supports easy installation and maintenance.

| Design Standard | Gate Valve - API 602 / ASME B 16.34 / ISO 15761 Standard Design Standard Globe Valve - BS 5352 / ASME B 16.34 / ISO 15761 Check Valve - BS 5352 / ASME B 16.34 / ISO 15761 Ball Valve - ISO 17292 / BS 5351 / BS 5159 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 / BS 5352 |

| End Connection | Screwed End To ANSI B 1.20.1 (BSP/NPT) Socket Weld End To ANSI B 16.11 Buttweld End To ANSI B 16.25 |

| Size Range | 1/4" Το 2" (DN6 Το DN50) (If higher sizes required, please do contact us) |

| Pressure Rating | 800# / 1500# |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/as requested) |

| Port/Bore | Reduced or Full Bore |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

The Weir Pattern Diaphragm Valve uses a unique weir-shaped seat to control flow with a flexible diaphragm, ensuring tight shutoff and precise regulation. Its design minimizes leakage and allows for effective handling of various fluids. Ideal for applications requiring reliable, leak-proof performance, it offers ease of maintenance and robust operation.

| Design Standard | BS EN 13397 (BS 5156) |

| Inspection & Testing Standard | BS EN 12266-1 ( BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | BS EN 13397 (BS 5156) |

| End Connection | Flanged End To ANSI B 16.5 / BS 10 Table D-E-F-H ; JIS/PN/DIN/ IS Standard |

| Size Range | 1/2" Το 8" (DN15 Το DN200) |

| Pressure Rating | PN10/150# |

| Operation | Hand Wheel / Pneumatic Actuator Operated |

The 3-Way Control Valve directs flow between three ports, allowing for versatile control of fluid routing and mixing. Its design enables precise flow regulation and switching between multiple pathways. Ideal for complex systems requiring flexible flow management, it ensures reliable performance and efficient operation.

Check valves (NRV) for preventing backflow and ensuring one-way fluid flow in your system.

Check valves, also known as non-return valves (NRVs), are designed to allow fluid to flow in one direction while preventing backflow. They operate automatically without the need for external control, using a hinged disc or ball mechanism that opens with forward flow and closes to block reverse flow. Ideal for protecting pumps and other equipment from damage caused by backflow, check valves ensure system integrity and operational efficiency by maintaining the correct direction of fluid movement.

| Design Standard | Swing Check Valve - BS 1868, Lift Check Valve - BS 1868 / BS 5352 / DIN Std. Wafer Type Check Valve - API 6D, Disc Type Check Valve - DIN EN 558-2 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 / API 6D |

| End Connection | Flanged end to ANSI B 16.10 / BS 10 Flanged End To ANSI B 16.5/BS 10 Table JIS / PN / DIN / IS Standard : Screwed End To ANSI B 1.20.1 (BSP/NPT), Socket Weld End To ANSI B 16.11 Buttweld End To ANSI B 16.25, Wafer Type, Flangeless, Sandwich Type |

| Size Range | 1/2" Το 12" (DN15 Το DN600) (If higher sizes required, please do contact us) |

| Pressure Rating | #150, #300, #600, #800, #900, #1500 |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |