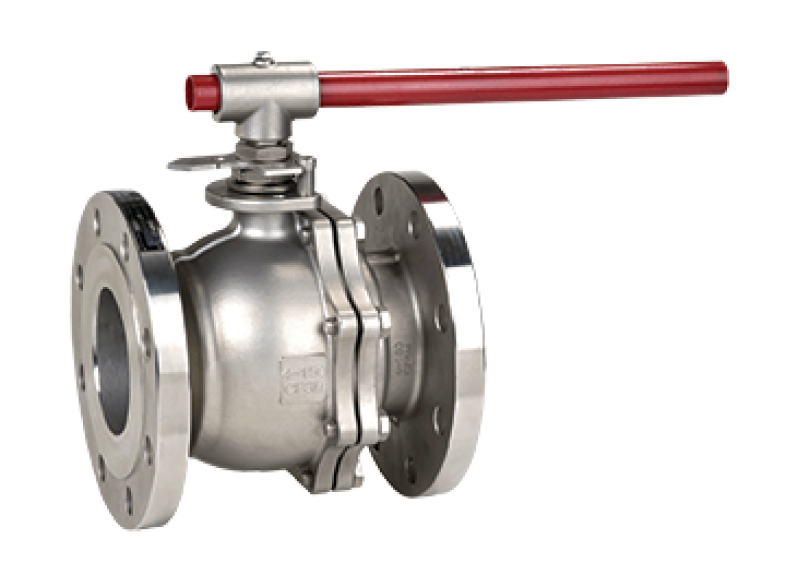

Floating ball valves have a ball that is not fixed but floats within the valve body, relying on fluid pressure to create a tight seal against the downstream seat when closed. This design ensures reliable sealing and simple operation. Ideal for various applications including water, oil, and gas, they effectively handle pressure changes and offer ease of maintenance.

| Design Standard | BS 5159 / ISO 7121 / BS 5351 / ISO 17292 / API 6D / API 608 / ISO 14313 / ASME B 16.34 / BS EN 12516 |

| Inspection & Testing Standard | API 598 / API 6D / BS EN 12266 - 1 / ISO 5208 |

| Fire Testing | API 607 / ISO 10497 / BS EN 12266 - II |

| Face to Face | As Per ANSI B 16.10 |

| End Connection | Flanged End To ANSI B 16.5 / BS 10 Table D-E-F-H / JIS / PN / DIN / IS Standard Screwed End To ANSI B 1.20.1 (BSP/NPT) Socket Weld End To ANSI B 16.11 |

| Size Range | 1/4’’ To 12’’ DN6 To DN300 (If higher sizes required, please do contact us) |

| Pressure Rating | 150# / 300# / 600# / 800# |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/as requested) |

| Port/Bore | Reduced or Full Bore |

| Type of Construction | 2 piece or 3 piece |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |