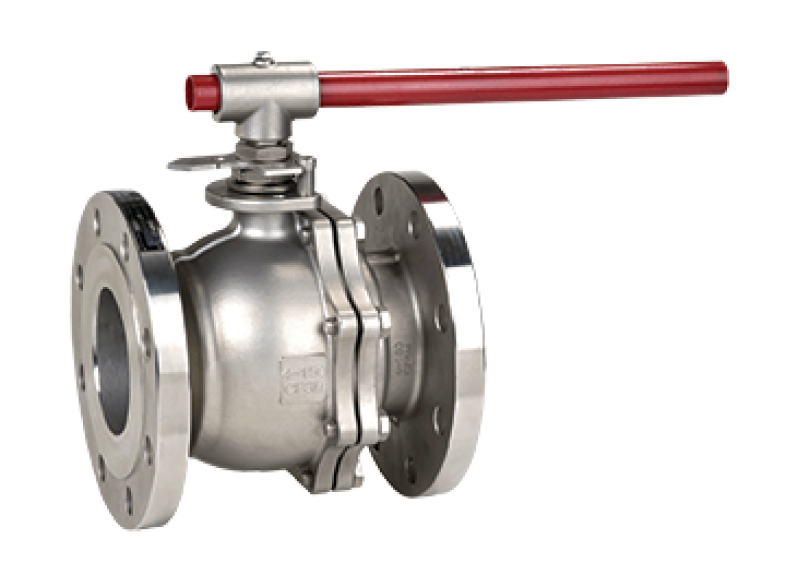

A trunnion ball valve features a ball supported by fixed trunnions, which stabilizes the ball and reduces operating torque. This design is ideal for high-pressure and high-temperature applications, offering reliable sealing and durability. It is commonly used in industries such as oil and gas, chemical processing, and power generation.

| Design Standard | BS 5159 / ISO 7121 / BS 5351 / ISO 17292 / API 6D / API 608 / ISO 14313 / ASME B 16.34 / BS EN 12516 |

| Inspection & Testing Standard | API 598 / API 6D / BS EN 12266 - 1 / ISO 5208 |

| Fire Testing | API 607 / ISO 10497 / BS EN 12266 - II |

| Face to Face | As Per ANSI B 16.10 |

| End Connection | Flanged End To ANSI B 16.5 / BS 10 Table D-E-F-H / JIS / PN / DIN / IS Standard Screwed End To ANSI B 1.20.1 (BSP/NPT) Socket Weld End To ANSI B 16.11 |

| Size Range | 50mm to 1000mm (If higher sizes required, please do contact us) |

| Pressure Rating | #150 / #300 / #600 / #800 / #900 / #1500 |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/as requested) |

| Port/Bore | Reduced or Full Bore |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

Single-piece ball valves are durable and simple but limited in size. Two-piece valves allow easier maintenance and cover more sizes, while three-piece valves offer the easiest maintenance with modular parts but are more complex and expensive. Each type balances durability, ease of service, and application needs.

| Design Standard | BS 5159 / ISO 7121 / BS 5351 / ISO 17292 / API 6D / API 608 / ISO 14313 / ASME B 16.34 / BS EN 12516 |

| Inspection & Testing Standard | API 598 / API 6D / BS EN 12266 - 1 / ISO 5208 |

| Fire Testing | API 607 / ISO 10497 / BS EN 12266 - II |

| Face to Face | As Per ANSI B 16.10 |

| End Connection | Flanged End To ANSI B 16.5 / BS 10 Table D-E-F-H / JIS / PN / DIN / IS Standard Screwed End To ANSI B 1.20.1 (BSP/NPT) Socket Weld End To ANSI B 16.11 |

| Size Range | DN15 To DN50 (If higher sizes required, please do contact us) |

| Pressure Rating | 150# / 300# / 600# / 800# |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/as requested) |

| Port/Bore | Reduced or Full Bore |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

Multiport ball valves for versatile flow management and efficient fluid distribution.

Multiport ball valves are versatile flow control devices that feature multiple ports, allowing them to direct flow to various paths within a system. Their design enables efficient fluid distribution and switching between multiple pipelines with a single valve, streamlining complex operations. Ideal for applications requiring flow diversion, mixing, or splitting, multiport ball valves offer compact solutions for managing fluid dynamics and enhancing system flexibility. Their ease of operation and reduced need for additional valves make them a cost-effective choice for optimizing flow management.

| Design Standard | BS 5159/ISO 7121 / BS 5351 / ISO 17292 / API 6D / ISO 14313/ASME B 16.34 / BS EN 12516 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | Mfg. Std. |

| End Connection | Flanged End To ANSI B 16.5 / BS 10 Table D-E-F-H JIS/PN/DIN/ IS Standard; Screwed End To ANSI B 1.20.1 (BSP/NPT) |

| Size Range | 1/2" Το 12" (DN15 Το DN300) (If higher sizes required, please do contact us) |

| Pressure Rating | 150# / 300# |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/as requested) |

| Port/Bore | Reduced or Full Bore |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

Jacketed ball valves for reliable flow control and thermal protection in extreme conditions.

Jacketed ball valves are designed to handle extreme temperature conditions by incorporating a surrounding jacket that maintains or adjusts the temperature of the media flowing through the valve. This design ensures reliable performance and prevents issues like freezing or overheating, making them ideal for processes that require consistent thermal management and robust flow control in demanding industrial environments. Their construction also enhances safety by preventing thermal shock and protecting against thermal stress.

| Design Standard | BS 5159/ISO 7121 / BS 5351 / ISO 17292/ API 6D / ISO 14313 / ASME B 16.34 / BS EN 12516 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 / Mfg. Std. / Special on request |

| End Connection | Flanged End To ANSI B 16.5 / BS 10 Table D-E-F-H/JIS/PN/ DIN / IS Standard |

| Size Range | 1/2" x 1" Το 6" x 10" (DN15 x DN25 Το DN100 x DN250) (If higher sizes required, please do contact us) |

| Pressure Rating | 150# / 300# |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/as requested) |

| Port/Bore | Reduced or Full Bore |

A half jacket ball valve has a partial jacket around the valve body to control fluid temperature, preventing issues like freezing or solidification. This design is ideal for applications requiring temperature management, such as in chemical processing or food production. It combines efficient flow control with effective temperature regulation.

| Design Standard | BS 5159 / ISO 7121 / BS 5351 / ISO 17292 / API 6D / ISO 14313 / ASME B 16.34 / BS EN 12516 |

| Inspection & Testing Standard | BS EN 12266 - 1 (BS 6755 - 1) / API 598 / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 / Mfg / Special on Request |

| End Connection | Flanged end to ANSI B 16.10 / BS 10 Table D-E-F-H / JIS / PN / DIN / IS Standard |

| Size Range | 1/2” x 1” To 6” x 10” (DN15 x DN25 To DN100 x DN250) (If higher sizes required, please do contact us) |

| Pressure Rating | 150# / 300# |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/as requested) |

| Port/Bore | Reduced or Full Bore |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

A full jacket ball valve has a jacket that completely surrounds the valve body, providing uniform temperature control. This design helps maintain consistent fluid temperatures and prevents issues like freezing or crystallization. It is ideal for applications in chemical processing and food production.

| Design Standard | BS 5159 / ISO 7121 / BS 5351 / ISO 17292 / API 6D / ISO 14313 / ASME B 16.34 / BS EN 12516 |

| Inspection & Testing Standard | BS EN 12266 - 1 (BS 6755 - 1) / API 598 / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 / Mfg / Special on Request |

| End Connection | Flanged end to ANSI B 16.10 / BS 10 Table D-E-F-H / JIS / PN / DIN / IS Standard |

| Size Range | 1/2” x 1” To 6” x 10” (DN15 x DN25 To DN100 x DN250) (If higher sizes required, please do contact us) |

| Pressure Rating | 150# / 300# |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/as requested) |

| Port/Bore | Reduced or Full Bore |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

Floating ball valves have a ball that is not fixed but floats within the valve body, relying on fluid pressure to create a tight seal against the downstream seat when closed. This design ensures reliable sealing and simple operation. Ideal for various applications including water, oil, and gas, they effectively handle pressure changes and offer ease of maintenance.

| Design Standard | BS 5159 / ISO 7121 / BS 5351 / ISO 17292 / API 6D / API 608 / ISO 14313 / ASME B 16.34 / BS EN 12516 |

| Inspection & Testing Standard | API 598 / API 6D / BS EN 12266 - 1 / ISO 5208 |

| Fire Testing | API 607 / ISO 10497 / BS EN 12266 - II |

| Face to Face | As Per ANSI B 16.10 |

| End Connection | Flanged End To ANSI B 16.5 / BS 10 Table D-E-F-H / JIS / PN / DIN / IS Standard Screwed End To ANSI B 1.20.1 (BSP/NPT) Socket Weld End To ANSI B 16.11 |

| Size Range | 1/4’’ To 12’’ DN6 To DN300 (If higher sizes required, please do contact us) |

| Pressure Rating | 150# / 300# / 600# / 800# |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/as requested) |

| Port/Bore | Reduced or Full Bore |

| Type of Construction | 2 piece or 3 piece |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |

Single-piece ball valves are durable and simple but limited in size. Two-piece valves allow easier maintenance and cover more sizes, while three-piece valves offer the easiest maintenance with modular parts but are more complex and expensive. Each type balances durability, ease of service, and application needs.

| Design Standard | Gate Valve - API 602 / ASME B 16.34 / ISO 15761 Standard Design Standard Globe Valve - BS 5352 / ASME B 16.34 / ISO 15761 Check Valve - BS 5352 / ASME B 16.34 / ISO 15761 Ball Valve - ISO 17292 / BS 5351 / BS 5159 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 / BS 5352 |

| End Connection | Screwed End To ANSI B 1.20.1 (BSP/NPT) Socket Weld End To ANSI B 16.11 Buttweld End To ANSI B 16.25 |

| Size Range | 1/4" Το 2" (DN6 Το DN50) (If higher sizes required, please do contact us) |

| Pressure Rating | 800# / 1500# |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/as requested) |

| Port/Bore | Reduced or Full Bore |

The Forged Steel Ball Valve features a robust construction designed for high-pressure and high-temperature applications. Its ball mechanism allows for quick and precise flow control with a simple quarter-turn operation. Durable and reliable, it ensures long-term performance in demanding environments. The valve’s design also supports easy installation and maintenance.

| Design Standard | Gate Valve - API 602 / ASME B 16.34 / ISO 15761 Standard Design Standard Globe Valve - BS 5352 / ASME B 16.34 / ISO 15761 Check Valve - BS 5352 / ASME B 16.34 / ISO 15761 Ball Valve - ISO 17292 / BS 5351 / BS 5159 |

| Inspection & Testing Standard | BS EN 12266-1 (BS 6755-1) / API 598 / ISO 5208 |

| Face to Face | As Per ANSI B 16.10 / BS 5352 |

| End Connection | Screwed End To ANSI B 1.20.1 (BSP/NPT) Socket Weld End To ANSI B 16.11 Buttweld End To ANSI B 16.25 |

| Size Range | 1/4" Το 2" (DN6 Το DN50) (If higher sizes required, please do contact us) |

| Pressure Rating | 800# / 1500# |

| Operation | Hand Lever, Gear, Pneumatic, Electrical Actuator (As applicable/as requested) |

| Port/Bore | Reduced or Full Bore |

| Temperature Range | -196 Deg C (Cryogenic application) to 550 Deg C ( High temperature) |

| Type of Seating | PTFE/EPDM/RPTFE/GFT/PEEK/DEVLON/METAL SEATED (As applicable/As requested) |